Award-Winning Engineering Project

My mousetrap-powered vehicle project for the Systems Engineering Module (SEM) at Saarland University resulted in a competition victory for being the fastest car. I designed and built an innovative lightweight vehicle that maximized speed through strategic engineering decisions.

The project challenged me to create a vehicle powered solely by mousetraps, with success measured by speed performance. My winning design combined 3D printing technology, lightweight materials, and precision engineering to create a vehicle weighing under 300 grams that outperformed all competitors.

My mousetrap-powered vehicle project for the Systems Engineering Module (SEM) at Saarland University resulted in a competition victory for being the fastest car. I designed and built an innovative lightweight vehicle that maximized speed through strategic engineering decisions.

The project challenged me to create a vehicle powered solely by mousetraps, with success measured by speed performance. My winning design combined 3D printing technology, lightweight materials, and precision engineering to create a vehicle weighing under 300 grams that outperformed all competitors.

Competition Achievements

🏆

Fastest Car Winner

<300g

Total Weight

SEM

University Project

1st

Place Winner

Design Process & Engineering Solutions

1

Drive System

Lever and String Propulsion

Initial concept using a lever mechanism connected to a string for power transmission from the mousetrap spring to the wheels.

Limited energy from single trap and complex lever mounting

3D-printed lightweight components with copper wire fixation for optimal energy transfer

2

Launch System

Catapult Mechanism

Second mousetrap configured as a catapult with string-based trigger system for projectile launching functionality.

Spoon durability under impact forces and unreliable string trigger

Increased wall thickness, broader design, and custom "hammer" trigger mechanism

3

Manufacturing

3D Printing & Material Selection

Strategic use of 3D printing technology combined with brass components to achieve optimal weight-to-strength ratio.

Balancing weight reduction with structural integrity

PLA and TPU materials for chassis, TPU tires for dampening, brass for precision components

4

Final Assembly

Testing & Optimization

Final assembly and testing phase resulted in immediate success with promising performance metrics.

Achieving consistent performance and reliability

Iterative testing, weight optimization under 300g, and fine-tuning of mechanical systems

Technical Specifications

Total Weight:

< 300g

Primary Material:

PLA (3D Printed)

Wheels:

TPU (Dampening)

Precision Parts:

Brass Components

Power Source:

Dual Mousetraps

Trigger System:

Custom Hammer Mechanism

Designer:

Felix Kuntz

Competition Result:

🏆 Fastest Car

Project Gallery

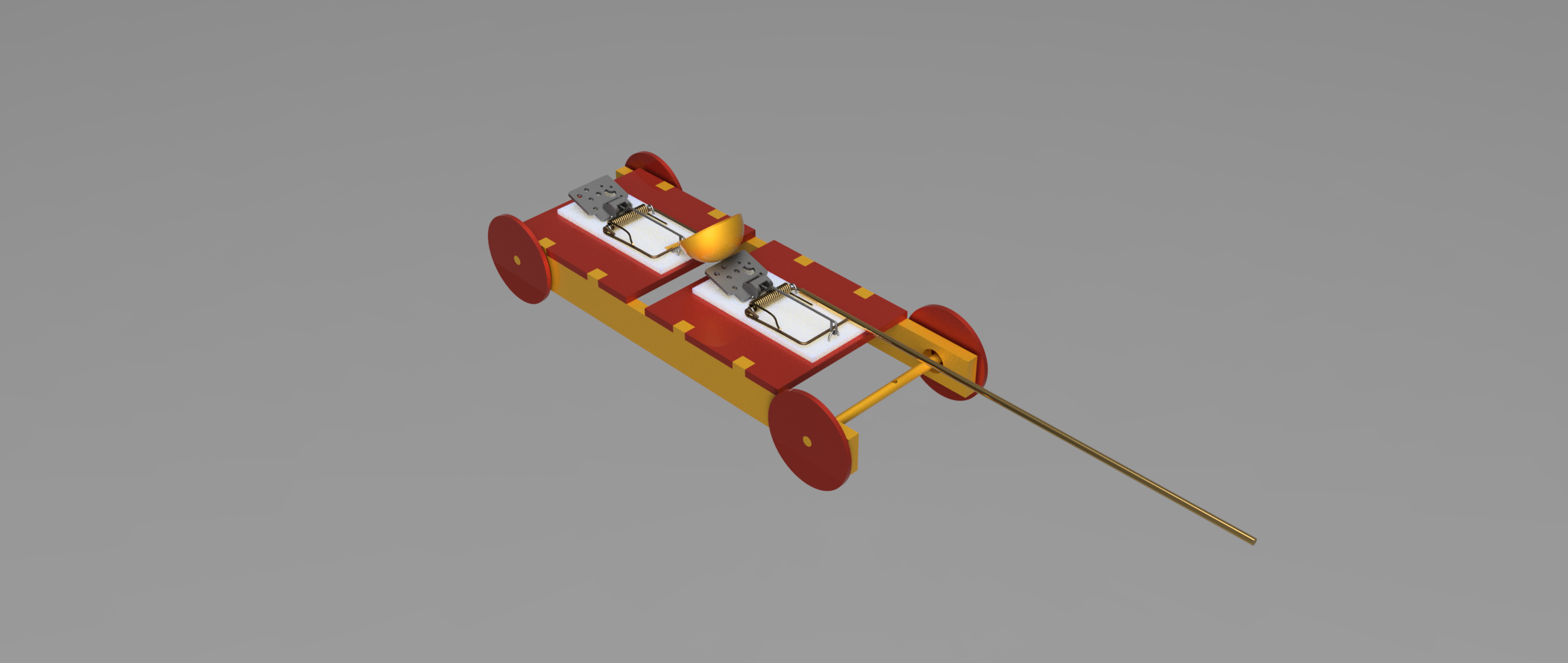

cad_design_isometric.png

CAD design showing the complete vehicle in isometric view. Features dual mousetrap configuration,

lightweight chassis design, and optimized wheel placement for maximum speed performance.

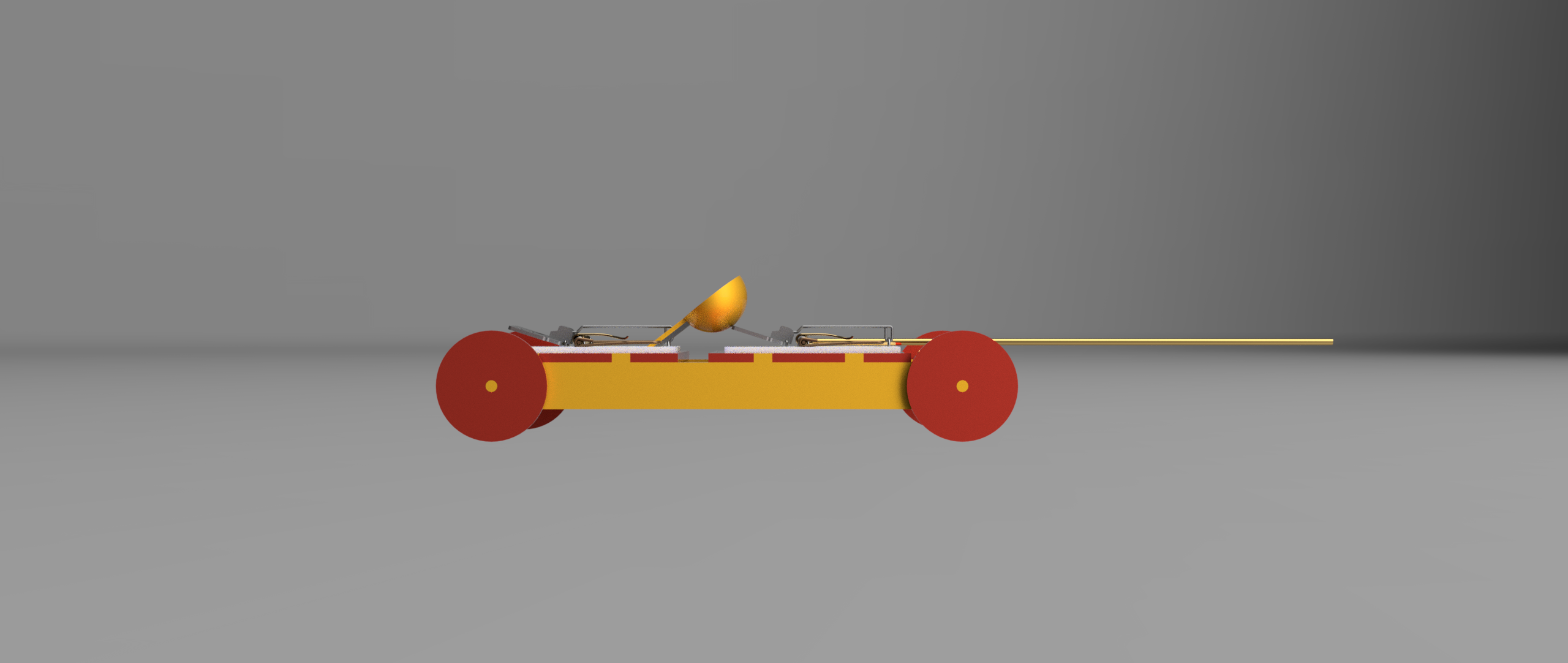

cad_design_side_profile.png

Side profile view of the winning design showing the aerodynamic profile and precise engineering

of the drive mechanism. The yellow launcher and red wheels demonstrate the careful material selection.

competition_demo.mov

Live demonstration of the award-winning mousetrap shooter in action, showcasing the speed

and precision that earned it first place in the fastest car competition.

Engineering Achievements

• Competition Victory: Won first place for fastest car in university-wide Systems Engineering competition.

• Weight Optimization: Achieved sub-300g weight through strategic material selection and 3D printing technology.

• Innovative Trigger System: Developed custom "hammer" mechanism solving reliability issues with traditional string triggers.

• Material Engineering: Strategic use of PLA, TPU, and brass components for optimal performance characteristics.

• Rapid Prototyping: Leveraged personal 3D printing capabilities for quick iterations and design optimization.

• Weight Optimization: Achieved sub-300g weight through strategic material selection and 3D printing technology.

• Innovative Trigger System: Developed custom "hammer" mechanism solving reliability issues with traditional string triggers.

• Material Engineering: Strategic use of PLA, TPU, and brass components for optimal performance characteristics.

• Rapid Prototyping: Leveraged personal 3D printing capabilities for quick iterations and design optimization.

Skills Demonstrated

CAD Design:

3D Modeling & Engineering

3D Printing:

Additive Manufacturing

Materials Science:

Multi-material Selection

Mechanical Design:

Kinematic Systems

Problem Solving:

Iterative Engineering

Team Collaboration:

Project Management