From Budget Printer to Professional Prototyping Tool

I started with a stock Ender 3 V2, but my goal was ambitious: push it to perform on the same level of speed as my Bambu Lab P1S. Step by step, I transformed it into a high-performance machine capable of 500 mm/s print speeds and up to 20,000 mm/s² acceleration.

What began as a budget printer is now a near-professional prototyping tool that comes close to my P1S in speed and efficiency. More than just hardware upgrades, this project taught me core principles of mechatronics, firmware optimization, and mechanical engineering, turning the Ender 3 V2 into a hands-on learning platform.

I started with a stock Ender 3 V2, but my goal was ambitious: push it to perform on the same level of speed as my Bambu Lab P1S. Step by step, I transformed it into a high-performance machine capable of 500 mm/s print speeds and up to 20,000 mm/s² acceleration.

What began as a budget printer is now a near-professional prototyping tool that comes close to my P1S in speed and efficiency. More than just hardware upgrades, this project taught me core principles of mechatronics, firmware optimization, and mechanical engineering, turning the Ender 3 V2 into a hands-on learning platform.

Performance Statistics

500

mm/s Max Speed

20,000

mm/s² Acceleration

~95%

P1S Performance Match

6+

Major Upgrades

Key Upgrades & Learning Outcomes

Extruder System

Orbiter V2.5 Extruder + Phaetus Hotend

Lightweight, high-torque setup for reliable extrusion at high speeds.

Dramatically improved print quality and reduced weight on the print head.

Learned: extrusion dynamics, retraction tuning, torque-to-weight optimization

Motion System

Linear Rails (X & Y Axes)

Replaced V-wheels with precision linear rails for smoother, more rigid motion system.

Eliminated play and improved positioning accuracy significantly.

Learned: CNC tolerancing and the mechanics of precision motion

Frame Stability

Dual Z-Axis + Frame Modifications

Enhanced gantry stability with dual Z-motors and reinforced frame structure.

Slightly increased X-height for better part clearance.

Learned: structural rigidity and stress distribution in mechanical systems

Auto-Leveling & Cooling

CR Touch + Hero Me 7 Cooling

Automated bed leveling for consistent first layers and optimized part cooling

airflow for high-speed printing without quality loss.

Learned: the balance of automation, mechanics, and cooling on print quality

Control System

BTT E3 V3.0 + Klipper Firmware

Advanced 32-bit control board with Klipper firmware featuring input shaping

and resonance compensation for high-speed printing stability.

Learned: system identification, firmware tuning, and motion control theory

Calibration Tools

Accelerometer Integration

Added accelerometer for automated resonance testing and input shaping

configuration, enabling optimal high-speed performance tuning.

Learned: vibration analysis and automated system optimization techniques

Before vs After Comparison

Specification

Stock Ender 3 V2

Custom Build

Max Print Speed

50-80 mm/s

500 mm/s

Acceleration

500-1000 mm/s²

20,000 mm/s²

Motion System

V-wheels on aluminum

Linear rails

Extruder

Bowden tube

Orbiter V2.5 direct drive

Auto-leveling

Manual bed leveling

CR Touch auto-leveling

Firmware

Marlin (basic)

Klipper + input shaping

Z-axis

Single motor

Dual motor system

Project Gallery

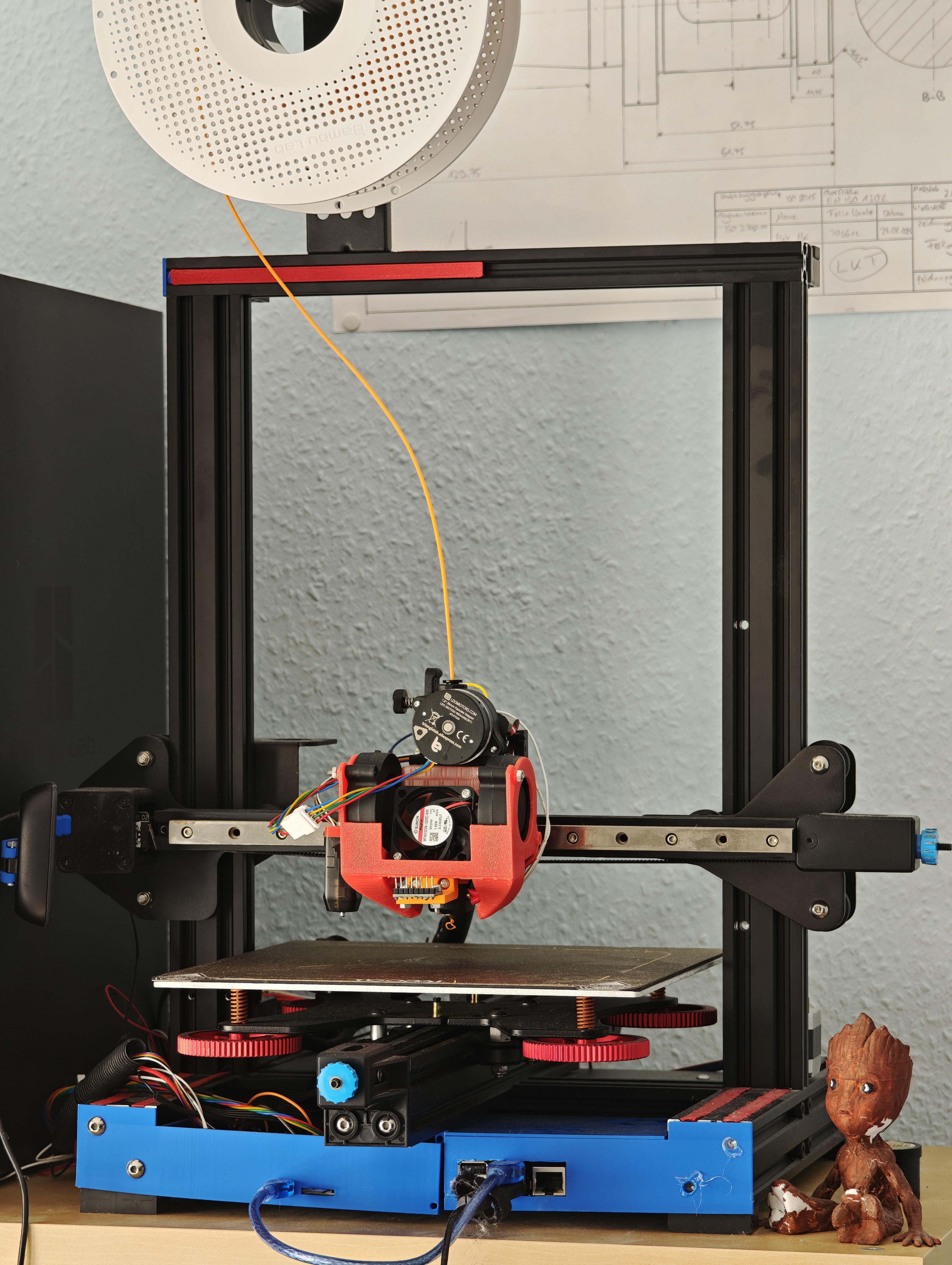

complete_build_overview.jpg

Complete build showing all major upgrades: linear rails, dual Z-axis, Hero Me 7 cooling shroud,

and the compact Orbiter extruder. Note the engineering drawings in the background and the

cute Groot figurine standing guard over the print bed.

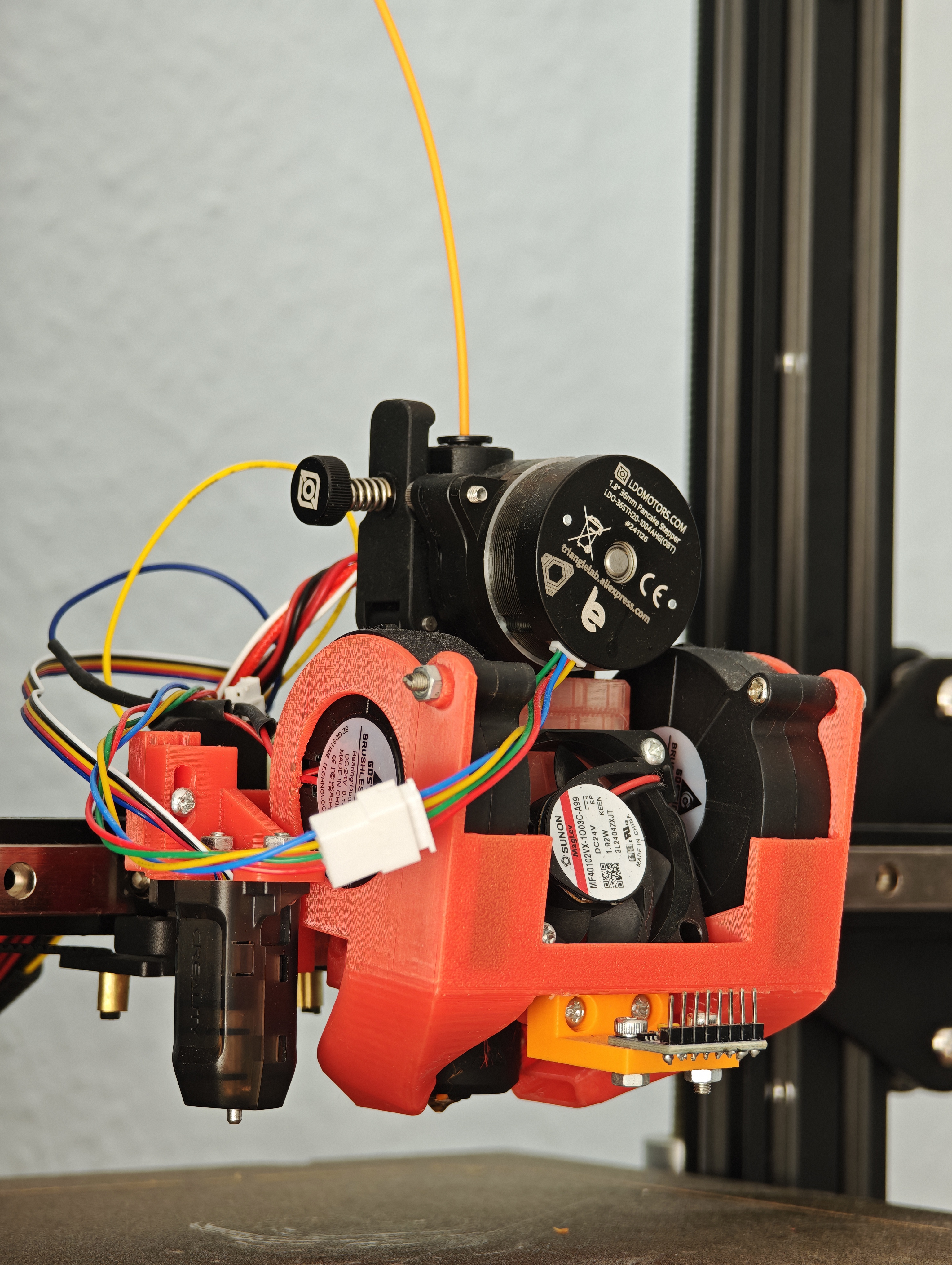

extruder_detail_closeup.jpg

Detailed view of the Orbiter V2.5 direct drive extruder with Phaetus hotend.

Shows the precision engineering of the lightweight design, optimized cable management,

and the Hero Me 7 cooling system with dual fans for optimal part cooling.

high_speed_printing_demo.mov

Live demonstration of high-speed printing capabilities showing the printer

operating at maximum performance with smooth, precise movements enabled by

the linear rail upgrades and Klipper firmware optimization.

Technologies & Skills Developed

• Mechatronics Integration: Understanding how mechanical, electrical, and software systems work together in precision machinery.

• Firmware Development: Configuring and optimizing Klipper firmware for maximum performance and reliability.

• Motion Control Theory: Learning about input shaping, resonance compensation, and vibration analysis.

• Mechanical Engineering: Frame rigidity, stress distribution, and precision motion system design.

• System Optimization: Using accelerometers and data analysis to achieve optimal performance tuning.

• Cost-Effective Engineering: Achieving professional-grade performance on a budget platform through strategic upgrades.

• Firmware Development: Configuring and optimizing Klipper firmware for maximum performance and reliability.

• Motion Control Theory: Learning about input shaping, resonance compensation, and vibration analysis.

• Mechanical Engineering: Frame rigidity, stress distribution, and precision motion system design.

• System Optimization: Using accelerometers and data analysis to achieve optimal performance tuning.

• Cost-Effective Engineering: Achieving professional-grade performance on a budget platform through strategic upgrades.

Technical Specifications

Component

Specification

Performance Gain

Mainboard

BTT E3 V3.0 32-bit

Advanced processing power

Extruder

Orbiter V2.5 Direct Drive

High torque, low weight

Hotend

Phaetus Dragonfly

High-temp, fast heating

Motion

MGN12H Linear Rails

Precision + rigidity

Firmware

Klipper + Input Shaping

500mm/s+ capability

Cooling

Hero Me 7 Dual Fan

High-speed cooling